Hydrogen Energy Industry

Throughout the entire hydrogen energy industry chain, we provide key ceramic materials and component solutions, offering reliable support for the efficient, safe, and long-life operation of hydrogen production, storage, transportation, and utilization,contributing to the commercialization and large-scale development of hydrogen energy technology.

1. Hydrogen production: core omponents of high-temperature electrolysis

Pain point:In high-temperature solid oxide electrolysis hydrogen production equipment, core components need to operate stably for extended periods in harsh environments exceeding 800°C.

Our solution: we supply core components such as ceramic electrolytes, electrodes, and connectors specifically designed for solid oxide electrolyzers (SOEC).

Value to you: ensuring efficient and stable ion conduction under high-temperature electrolysis conditions, helping to improve hydrogen production efficiency and equipment lifespan, and reducing the cost of green hydrogen production.

2. Storage and transportation: safety and purity control

Scenarios and pain points: hydrogen storage and transportation face challenges such as hydrogen embrittlement, permeability, and high pressure, and the raw hydrogen requires purification.

Our solution: we provide corrosion-resistant ceramic inner wall coatings for hydrogen storage tanks, as well as porous ceramic supports and catalyst support materials required for hydrogen purification.

Value to you: enhances the safety and durability of storage and transportation equipment while improving hydrogen purification efficiency, providing a reliable guarantee for the large-scale application of hydrogen energy.

3.Hydrogen utilization: long-life fuel cell support

Scenarios and pain points: fuel cells need to operate for extended periods under harsh conditions such as strong acids and high temperatures, making traditional materials susceptible to corrosion and aging.

Our solution: we provide corrosion-resistant composite ceramic bipolar plates, battery connectors, high-temperature sealing materials, and electrolyte and electrode components for solid oxide fuel cells.

Value to you: Ceramic bipolar plates boast a corrosion-resistant lifespan exceeding 10,000 hours, significantly improving the durability and economics of fuel cell stacks and accelerating the commercialization of fuel cells.

We focus on providing high-performance ceramic solutions for all aspects of the hydrogen energy industry, and through material innovation, we help hydrogen energy technology achieve more efficient, safer, and more economical large-scale development.

Wind Turbines

In the field of high-reliability operation of wind power equipment, we provide high-performance ceramic component solutions to address the corrosion, wear, and insulation challenges faced by offshore and onshore wind turbines, helping to improve the durability and power generation efficiency of wind turbine drive systems.

1.Protection Against Corrosion and Wear in Transmission Systems

Scenarios and Pain Points: Core transmission components such as the fan shaft and gearbox are susceptible to corrosion and electrochemical erosion in humid and salt spray environments, affecting the long-term reliable operation of the equipment.

Our solution: we provide high-performance Ceramic Coatings, all-ceramic or hybrid Ceramic Bearings, and ceramic insulating gaskets to strengthen and insulate critical components.

Value to you: ceramic protection can extend the lifespan of bearings and other components by 3-5 times, significantly reducing maintenance downtime caused by corrosion and wear, and helping to ensure stable operation of the fan throughout its entire lifespan.

2.Improving Transmission Efficiency and Stability

Pain points: traditional bearings experience high frictional losses under high loads and variable speed conditions. Lubrication solutions are temperature-limited and pose a risk of leakage, impacting transmission efficiency.

Our Solution: we offer self-lubricating ceramic coatings, ceramic rolling elements, and specialized low-friction bearing assemblies, optimizing the transmission contact interface.

Value to you: effectively reduces frictional losses during transmission, decreases reliance on lubrication, and improves the operational stability and power generation efficiency of wind turbines in various environments.

We focus on solving key durability and efficiency issues in wind turbine drive systems through ceramic material technology, helping the wind power industry achieve long-term stable operation with lower maintenance costs and higher power generation revenue

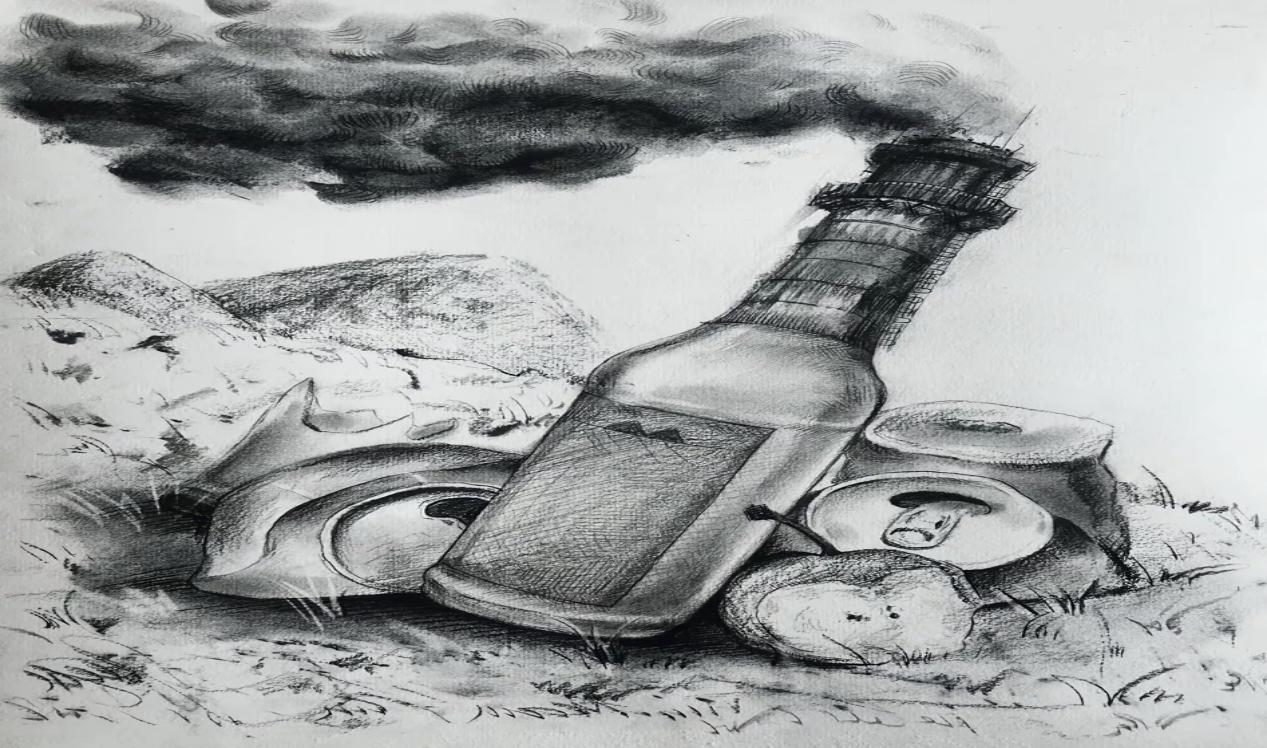

Exhaust Gas Purification

In the field of industrial waste gas and exhaust gas treatment, we provide high-performance ceramic carriers and filter component solutions to cope with harsh operating conditions such as high temperature, high dust, and high corrosion, helping to achieve efficient purification, stable operation, and long-term emission compliance.

1.Scenarios and Pain Points: Increasingly stringent emission regulations require exhaust treatment systems to maintain high-efficiency catalytic conversion capabilities at high temperatures.

What we can do: we provide cordierite and silicon carbide Honeycomb Ceramic carriers as the core substrate for three-way catalytic converters and particulate filters.

How can we help you: The ceramic carrier provides a stable adhesion surface for the catalyst, ensuring the efficient conversion of harmful components in exhaust gases at high temperatures, helping you continuously meet environmental regulations.

2.Industrial High-Temperature Flue Gas Treatment

Scenarios and pain points: high-temperature flue gas from industries such as steel and power has high dust content and is highly corrosive. Traditional filter media have short lifespans and unstable operation.

What We Can Do: We provide high-temperature resistant Ceramic Filter tubes and Porous Ceramic Filter, enabling direct filtration in high-temperature environments.

What we achieve for you: ceramic filter tubes can withstand temperatures above 1000℃ and acid/alkali corrosion, achieving highly efficient dust removal, reducing system cooling energy consumption, significantly extending filter media lifespan, and ensuring continuous clean operation of industrial kilns.

We focus on providing reliable ceramic filter media for the treatment of exhaust gases from both mobile and stationary sources, to cope with harsh operating conditions of high temperature and high dust, and to achieve long-term and stable purification effects.

Water treatment

In the field of water treatment and resource recovery, we provide high-performance ceramic filtration and functional component solutions to address complex water quality conditions and stringent process requirements, helping to achieve efficient separation, deep purification and stable operation, and supporting the goals of water resource recycling and zero discharge.

1. Deep purification and reuse of industrial wastewater

Customer pain points: Wastewater from industries such as electronics and electroplating has complex composition, making it difficult for traditional processes to consistently meet standards and easily causing secondary pollution.

What we can do: provide Ceramic Membranes for physical retention, and supply ceramic carriers loaded with special functional materials for adsorption and catalytic degradation.

We help you achieve: efficient removal of heavy metals and other pollutants with stable filtration precision, reducing reliance on chemical agents and sludge production, and enabling wastewater reuse and stable discharge that meets standards.

2.Addressing the challenges of improving wastewater biological treatment efficiency

Customer pain points: traditional aeration equipment is prone to clogging, has low oxygen utilization, and the biological carrier is susceptible to aging, leading to unstable treatment efficiency and high energy consumption.

What we can do: provide Porous Ceramic aerators and high specific surface area ceramic biological packing materials.

What we help you achieve: aerators generate fine bubbles, improving oxygen utilization and preventing clogging; biological packing materials provide a stable attachment environment for microorganisms, enhancing treatment capacity, and together helping you reduce aeration energy consumption and operating costs.

We focus on providing core filtration and functional components for various water treatment scenarios, leveraging the stable performance and long lifespan of ceramic materials to help you achieve the comprehensive goals of improving water quality, recycling resources, and optimizing costs.

Solid Waste Disposal

In the field of solid waste treatment and resource recovery, we provide high-performance ceramic refractory materials and functional component solutions, providing reliable material support for key processes such as high-temperature incineration, melt stabilization and flue gas purification, and helping to achieve efficient treatment, safe emissions and resource recycling.

1. Furnace body protection for high-temperature incineration and melting

Customer pain points: The interiors of waste and hazardous waste incinerators are highly corrosive and hot, and traditional refractory materials have short lifespans, affecting continuous operation and heavy metal stabilization.

What we can do: provide corrosion-resistant ceramic linings, specialty refractory materials, and ceramic matrix materials for heavy metal solidification.

What we help you achieve: protect the furnace body from high-temperature corrosion, extending furnace lining life; promote glass phase formation, stabilize and solidify heavy metals, reduce leaching risk, and help you improve system operational continuity and disposal safety.

2. Addressing flue gas purification and fly ash stabilization

Customer pain points: incineration flue gas contains dioxins, acidic gases, and heavy metal dust. Traditional filter media are prone to failure at high temperatures, and fly ash treatment poses environmental risks.

What we can do: Provide high-temperature ceramic filters, catalytic filter tubes, and ceramic-based cementitious materials for fly ash stabilization.

What we can achieve for you: high-efficiency dust filtration and synergistic dioxin degradation at high temperatures; stabilize heavy metals in fly ash, reduce leaching toxicity, and provide you with an integrated flue gas purification and safe fly ash disposal solution to ensure compliance with emission standards.

Leave A Message

Scan to Wechat :

Scan to WhatsApp :