Industrial Ceramic Parts Reshape the Boundaries of Automotive Performance

In today's automotive industry, which pursues ultimate performance, ultra-long lifespan, and green transformation, a seemingly traditional material is quietly triggering a silent revolution—Custom Ceramic Parts are moving from laboratories and racetracks into the mainstream automotive manufacturing field.

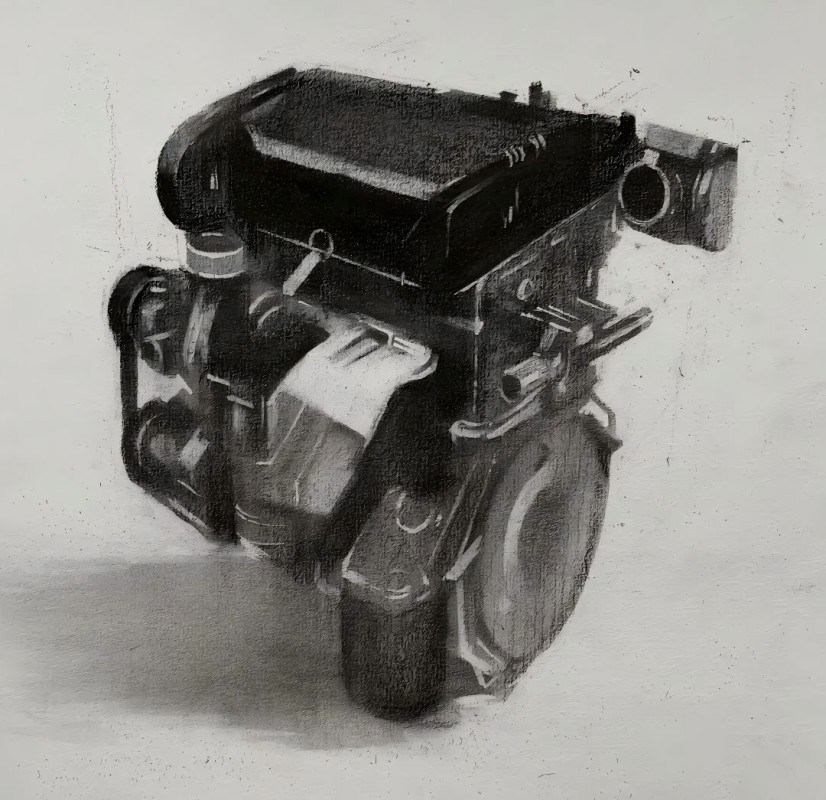

Powertrain

In the fields of automotive electrification and powertrain systems, we provide high-performance Ceramic Solutions to help address the stringent challenges of high heat dissipation, high responsiveness, and high temperature resistance, providing critical support for achieving higher efficiency, reliability, and driving performance in powertrain systems.

1. Electric Drive and Fuel Cell Thermal Management

Industry Scenario: In new energy vehicles, the heat dissipation and insulation capabilities of the motor, electronic control system, and fuel cell directly impact system power output, efficiency, and long-term reliability when operating under continuous high loads.

Ceramic Solutions: We provide aluminum nitride Ceramic Heat Sinks, high-insulation Ceramic Gaskets, corrosion-resistant ceramic flow channels, and composite ceramic bipolar plates for fuel cells. Through high thermal conductivity and chemically stable structures, we achieve efficient thermal management and dielectric isolation.

Core Value: We systematically solve the heat dissipation and electrical insulation challenges of high-power components. We help customers improve system heat dissipation efficiency and electrical safety, support continuous high power output, facilitate higher power density and longer service life, and provide a reliable thermal management foundation for electrification platforms.

2.High-Efficiency Turbocharging Response

Industry Scenario: In turbocharging systems, traditional metal turbine blades, due to their heavy weight and high inertia, cause sluggish boost response, affecting low-speed torque and acceleration smoothness.

Ceramic Solution: We offer lightweight silicon nitride Ceramic Turbine Blades and Ceramic Bearing assemblies, replacing metal with high-strength, lightweight materials to reduce the inertia of rotating components.

Core Value: Significantly improves turbo lag and enhances power response. Our Ceramic Blades can achieve a weight reduction of approximately 40%, helping to improve turbocharger response speed by approximately 30%, optimizing low-speed torque output and acceleration experience, and improving overall vehicle driving performance.

3.Precise Engine Emission Control

Industry Scenario: Engines require real-time, precise oxygen concentration monitoring in exhaust environments exceeding 800°C to control the air-fuel ratio, meet stringent emission regulations, and improve combustion efficiency.

Ceramic Solution: We provide high-temperature resistant zirconia ceramic sensor cores and heat-resistant Ceramic Sheaths to ensure stable operation in high-temperature, corrosive exhaust environments.

Core Value: Ensuring the monitoring accuracy and signal stability of emission systems in extreme environments. Our ceramic sensor components provide electronic control units with long-term reliable oxygen concentration data, supporting cleaner combustion and lower emissions, while also contributing to improved fuel economy.

We focus on providing high-performance ceramic solutions for automotive powertrains, from thermal management and boost response to underlying sensing, using materials technology to help automobiles move towards a more efficient and cleaner future.

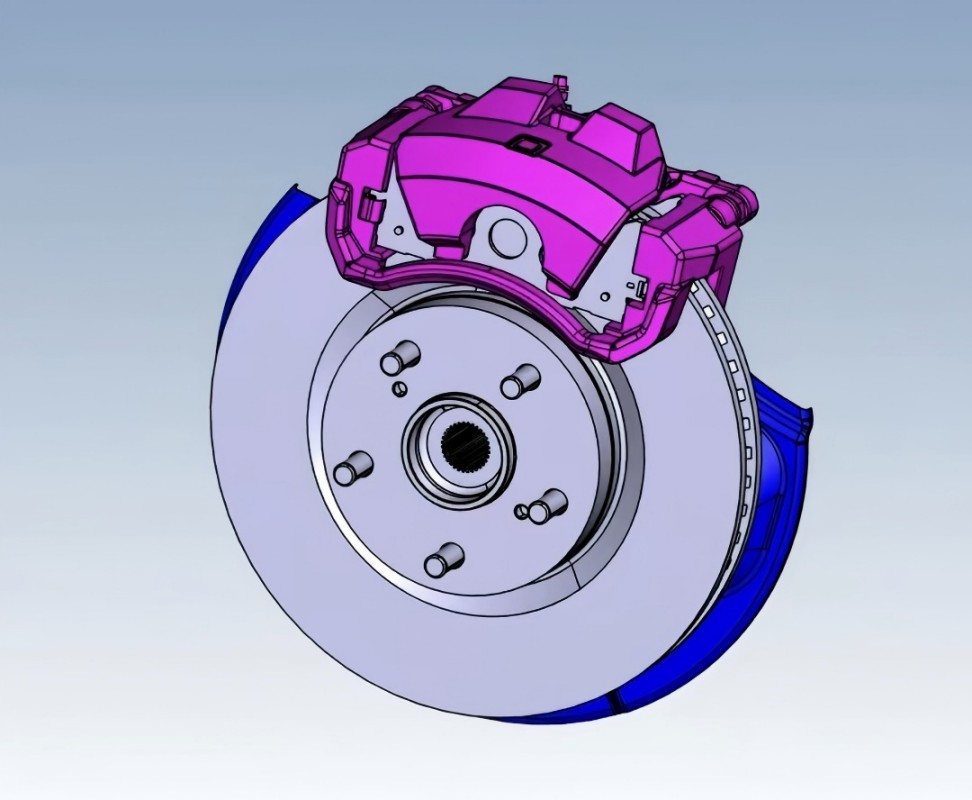

Braking System

In the automotive braking field, we provide high-performance Ceramic Parts solutions to help OEMs and users achieve safer, more durable, and more economical braking performance.

1. Braking Upgrades

Industry Scenarios: In high-performance sports cars, luxury cars, and new energy vehicles, traditional brake discs are prone to heat fade during continuous high-intensity braking, affecting safety. In addition, they are heavy, produce a lot of dust, and are not conducive to range and aesthetics.

Ceramic Solutions: We offer silicon carbide ceramic composite brake discs and matching low-metal brake pads. Through ceramic fiber reinforcement and high-temperature resistant formulation design, we achieve excellent thermal shock resistance and wear resistance.

Core Value: Systematic solutions to heat fade, weight, and dust issues. Ceramic Brake Discs can withstand temperatures up to 1400℃, resulting in more stable braking performance; weight reduction of over 50% improves handling and fuel efficiency; extremely low dust emissions keep wheel hubs clean, meeting the comprehensive safety, range, and quality requirements of high-performance and new energy vehicles.

2. Extended Service Life

Industry Scenarios: Commercial vehicle fleets and high-end passenger car users prioritize the total lifecycle cost of braking systems, aiming to extend replacement intervals, reduce maintenance frequency, and ensure long-term operational economy and reliability.

Ceramic Solutions: We offer long-life ceramic composite brake discs and dedicated wear-resistant brake pads suitable for various vehicle models, with optimized material formulations for daily and medium-to-high-intensity use environments.

Core Value: Significantly extends the lifespan of braking components and reduces overall operating costs. Ceramic brake discs can last 2-3 times longer than traditional cast iron discs, drastically reducing replacement frequency and downtime, helping fleets and individual users save on maintenance costs throughout the entire lifecycle and achieve more economical long-term braking protection.

We are committed to providing high-performance, long-life ceramic braking solutions for different vehicle models and usage scenarios, helping to achieve a safer, cleaner, and lower-cost driving experience.

Electrification Systems

In the electrification systems of new energy vehicles, we provide high-performance ceramic component solutions to help OEMs and component suppliers address key challenges such as high-power heat dissipation, high-voltage insulation, and fuel cell durability.

1.High-Power Heat Dissipation for Electronic Control Systems

Industry Scenario: Power modules such as SiC operate at high temperatures and high power. Traditional heat dissipation solutions struggle to meet long-term stability and reliability requirements, hindering performance improvements in electronic control systems.

Ceramic Solution: We offer aluminum nitride (AlN) and alumina ceramic substrates and copper-clad ceramic liners. Through an integrated design combining high thermal conductivity and insulation, we achieve efficient heat conduction between the chip and the heat sink.

Core Value: Significantly improves the heat dissipation capacity and reliability of electronic control systems. Our Ceramic Substrate for Electronic Control Power Modules can help customers improve heat dissipation efficiency by over 35%, supporting stable operation of power modules above 200℃, thereby increasing power density and extending system lifespan.

2. Electrical Safety Assurance for High-Voltage Platforms

Industry Scenario: High-voltage platforms of 800V and above place extremely high demands on the withstand voltage and aging resistance of insulation materials. Traditional materials pose a risk of breakdown, affecting system safety.

Ceramic Solutions: We provide Ceramic Insulating, ceramic structural components for battery module spacing, and ceramic components for high-voltage connections. These materials possess high dielectric strength and stable chemical properties.

Core Value: Providing a long-term, reliable insulation barrier for high-voltage systems. Ceramic Insulation have a breakdown voltage of up to 20kV/mm and are not prone to aging, helping customers improve the overall safety level of battery packs and electrical systems, meeting the stringent insulation life requirements of high-voltage platforms.

3. Long-Life, Low-Cost Fuel Cell Applications

Industry Scenarios: Fuel cell bipolar plates need to operate long-term in strong acid and high-potential environments. Traditional graphite and metal plates have shortcomings in corrosion resistance, cost, or impact resistance, limiting stack life and economics.

Ceramic Solutions: We offer composite ceramic bipolar plates and specialized anti-corrosion ceramic coatings, balancing conductivity, corrosion resistance, and mechanical strength through material optimization.

Core Value: Improving durability while reducing overall costs. Our ceramic bipolar plates have a corrosion resistance life exceeding 10,000 hours and cost approximately 40% less than graphite plates, helping customers extend stack life and optimize the total cost of ownership for fuel cell systems.

We focus on providing highly reliable and cost-effective ceramic solutions for core electrification systems, helping new energy vehicles achieve safer, more efficient, and more competitive performance.

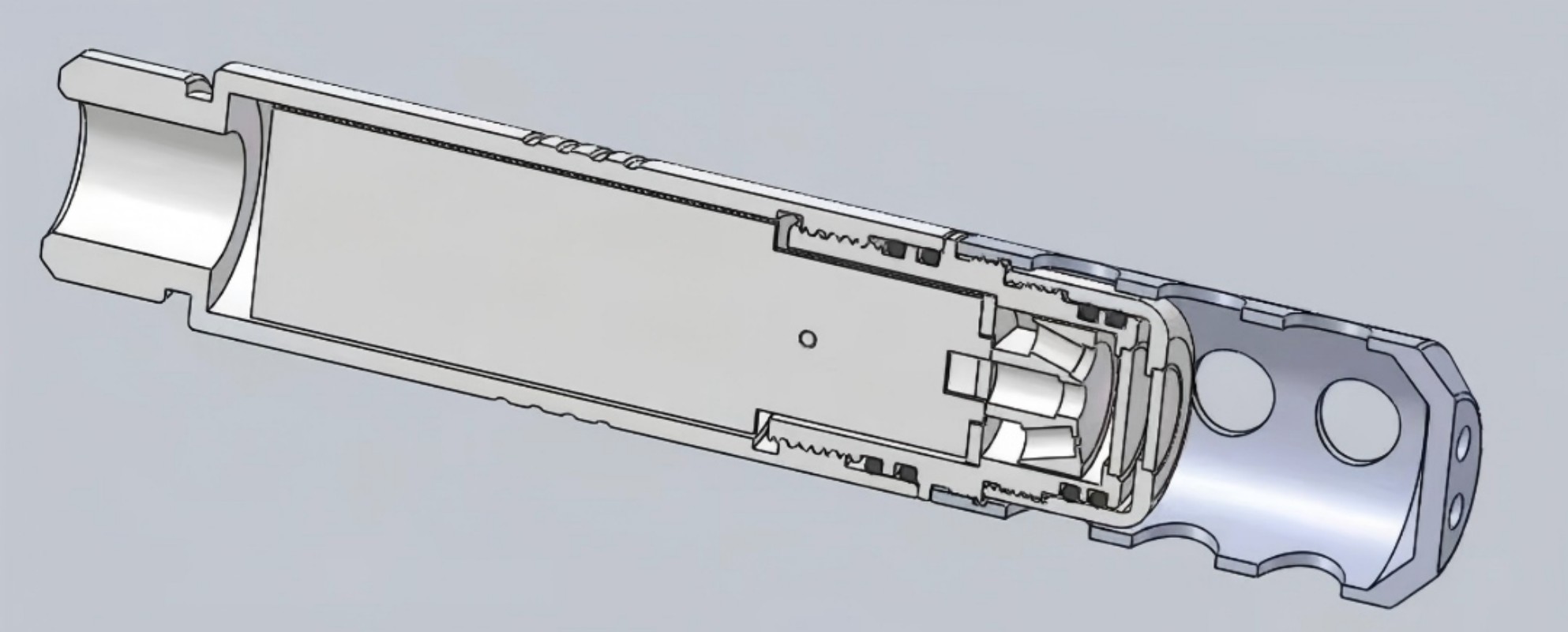

Sensing system

In the field of automotive sensing and electronic control, we provide high-performance ceramic component solutions to help achieve more stable and accurate signal perception, providing reliable protection for vehicle safety and intelligence.

1.Precise Monitoring of Engine and Chassis Systems

Industry Scenarios: Critical sensors for engine knock, crankshaft position, and other applications require long-term operation in high-temperature, vibration, and oil-contaminated environments. Signal accuracy directly impacts power efficiency and chassis stability.

Ceramic Solutions: We provide ceramic chip and ceramic substrates, Piezoelectric Ceramic elements, and high-temperature resistant ceramic encapsulation. These materials possess excellent thermal stability and mechanical strength.

Core Value: Ensuring sensor signal stability under extreme conditions. Our ceramic components help customers achieve precise sensor operation across a wide temperature range of -40℃ to 1000℃, improving signal response and reliability, and optimizing engine combustion and chassis control performance.

2.Reliable Level and Pressure Sensing

Industry Scenarios: Monitoring the level and pressure of fluids such as fuel and brake fluid requires prolonged contact with corrosive media. Traditional materials are prone to signal drift or failure, impacting vehicle safety and emissions management.

Ceramic Solution: We provide Ceramic Capacitors/piezoresistive sensor cores, ceramic diaphragms, and corrosion-resistant structural components to achieve media isolation and stable measurement.

Core Value: Providing a long-lasting, stable, media-compatible measurement solution. Our ceramic components resist corrosion from various liquids and gases, maintaining measurement consistency, reducing false alarms, and providing continuous and reliable data for vehicle safety and emissions control.

3.Intelligent Driving Environmental Perception

Industry Scenario: Radar and lidar windows must maintain signal transmittance and physical protection under harsh conditions such as rain, snow, and sandstorms to ensure reliable operation of autonomous driving assistance functions.

Ceramic Solution: We provide low-loss Ceramic Radomes, high-transmittance ceramic windows, and scratch-resistant protective layers, balancing electromagnetic performance and mechanical protection.

Core Value: Enhancing the all-weather capability of environmental perception sensors. Our ceramic transmittance components maintain stable signal transmittance in complex climates and provide excellent physical protection, extending sensor lifespan and ensuring the reliability of environmental data from intelligent driving systems.

We focus on providing highly stable, environmentally resistant ceramic core components for automotive sensing systems, helping to improve vehicle safety, intelligence, and long-term reliability.

Leave A Message

Scan to Wechat :

Scan to WhatsApp :