Ceramic components are the "precision engineering core" and "shield of life" in the medical field. Their superior biocompatibility, extreme chemical inertness, and wear resistance ensure the precision and reliability of in vitro diagnostic equipment and surgical instruments, while their unique electrical and thermal properties drive the core functions of ultrasound, imaging, and therapeutic devices.

At the boundary between biology and technology, they build a safe, durable, and powerful bridge, directly improving diagnostic and treatment accuracy, patient quality of life, and medical equipment efficiency. They are indispensable cornerstone materials in modern high-end medicine.

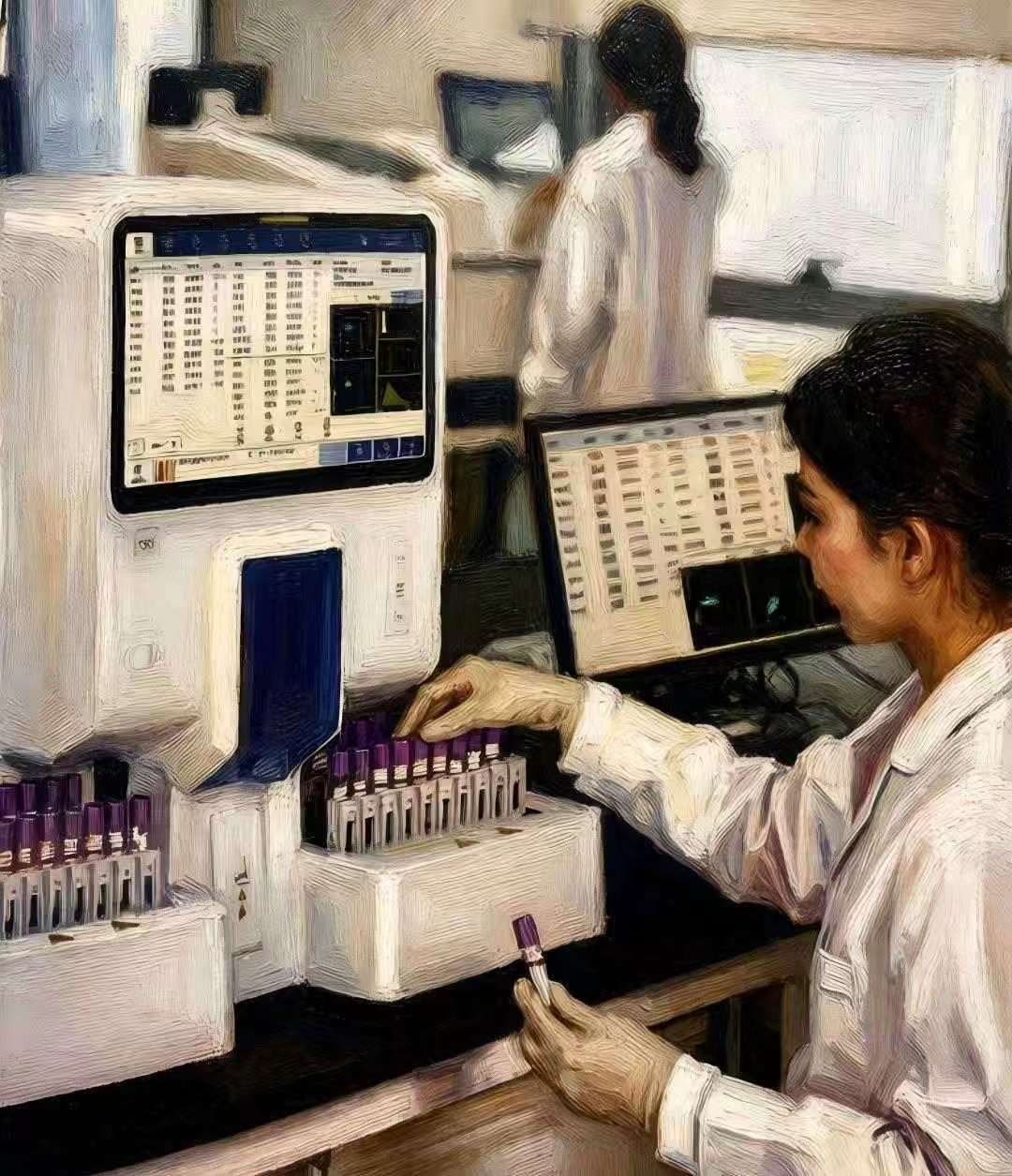

Blood analyzer

In the fields of in vitro diagnostics and blood analysis, we provide high-performance ceramic component solutions, offering crucial support for the high precision, high reliability, and long lifespan of testing equipment. Their superior chemical inertness ensures zero contamination and zero interference during the transport, mixing, and reaction of blood samples and reagents.

1.Contamination-Free Sample and Reagent Delivery

Industry Scenario: Blood and biochemical reagents are highly corrosive. Traditional metal or polymer components within the instrument's flow path may release ions or dissolve, interfering with the reaction system and leading to inaccurate test results.

Ceramic Solution: We provide precision flow channels, mixing chambers, reaction cups, and connectors made of Zirconium Oxide Ceramics or Alumina Ceramics, ensuring that all surfaces in contact with samples and reagents are inert.

What We Provide: Fundamentally eliminate the risk of false positives/false negatives caused by flow path contamination. Our ceramic components are chemically absolutely stable and do not react with any biochemical substances, guaranteeing "zero interference" throughout the entire process from sample aspiration to result output, ensuring absolute accuracy of test results.

2.Long-Life Precision Control for Quantitative and Dispensing Systems

Industry Scenarios: High-precision quantitative pumps, dispensing valves, and sampling needles in instruments are prone to wear under long-term, high-frequency operation, leading to increased dispensing volume errors. This directly affects the repeatability and accuracy of testing, requiring frequent calibration and maintenance.

Ceramic Solutions: We provide ceramic quantitative pump plungers, ceramic valve cores and seats, ceramic syringe liners, and sampling needles. These components feature mirror-like finish and ultra-high hardness.

What We Achieve: Extend the lifespan of core moving parts by an order of magnitude while maintaining precision. The ultra-high wear resistance of ceramics ensures that microliter-level dispensing volumes remain constant after millions of cycles, significantly reducing accuracy drift caused by component wear, minimizing maintenance and calibration frequency, and guaranteeing long-term stable factory accuracy of the equipment.

3. Electrical Insulation and Biosafety Protection

Industry Scenario: During the testing process, absolute insulation is required for electrode signal measurement, capacitance level detection, and other steps; simultaneously, disposable components must prevent cross-contamination between different samples.

Ceramic Solution: We provide Ceramic Insulating Substrates, Ceramic Electrode Sleeves, Ceramic Pipette Tips, etc.

What We Achieve: We provide a pure environment for precision electrical signal measurement and a physical barrier for biosafety. The perfect insulation of ceramics ensures that weak detection signals are not interfered with; disposable ceramic pipette tips can be incinerated at high temperatures after use, leaving no harmful residues, while their high-hardness surface prevents sample residue, achieving the highest level of protection against cross-contamination.

We focus on providing high-performance ceramic core components for in vitro diagnostic devices, covering the entire process from flow path and dispensing to testing. With the ultimate stability and biosafety of the materials, we safeguard the accuracy and reliability of every test report.

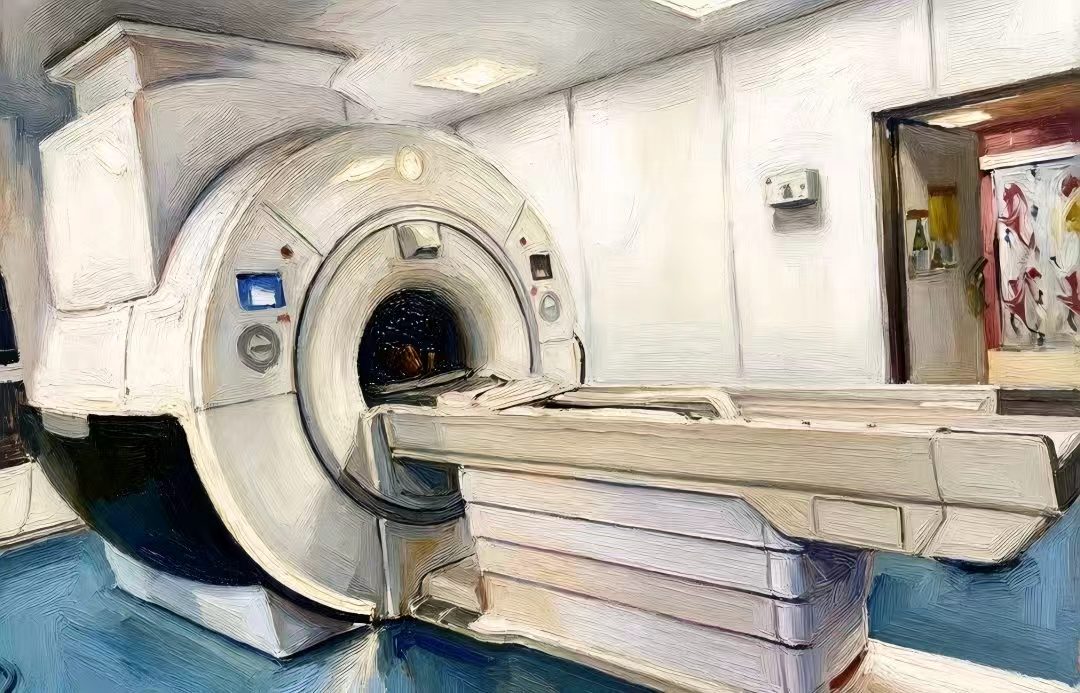

Medical Imaging

In the field of medical imaging, ceramic components, with their extreme physical and chemical stability, ensure zero interference, zero drift, and long lifespan operation of the imaging link under extreme conditions such as high speed, high pressure, strong magnetism, and high radiation of imaging equipment.

1. CT Equipment: Stable and Maintenance-Free Slip Ring System

Scenarios and Pain Points: CT slip rings need to transmit power and signals while rotating at high speeds. Metal brushes are prone to wear, leading to poor contact, noise, and frequent maintenance, affecting imaging stability and equipment uptime.

What We Can Do: We provide High-performance Ceramic Brushes and insulating components to replace traditional metal brushes.

What We Achieve for You: Ceramic brushes experience virtually no wear, ensuring long-term stable transmission of power and data signals under high-speed rotation, achieving a "maintenance-free" design for the slip ring system, and significantly improving equipment reliability and imaging consistency.

2.MRI Equipment: Interference-Free Structural Guarantee in Strong Magnetic Fields

Scenarios and Pain Points: Superconducting magnets and radio frequency coils need to maintain absolute structural stability in strong magnetic fields. Any metal or magnetic material will interfere with magnetic field homogeneity, leading to image artifacts.

What We Can Do: Provide absolutely non-magnetic Ceramic Insulating supports, radio frequency coil substrates, and structural frames.

How We Achieve It: Our ceramic components are completely non-magnetic and eddy current-free in strong magnetic fields, providing stable and pure physical support for the magnets and coils, ensuring magnetic field homogeneity, and eliminating image distortion caused by structural materials at its source.

3.X-ray Equipment: Precise Control and Protection Against High-Energy Radiation

Scenarios and Pain Points: X-ray tube windows must withstand high-energy radiation while allowing efficient radiation penetration. Components such as the grid require precise control of the beam and reduction of scattered radiation. Traditional materials are prone to aging and lack sufficient precision.

What We Can Do: We provide radiation-resistant Ceramic X-ray Tube Windows, high-precision Ceramic Grid Blades, and collimator assemblies.

What We Achieve for You: Ceramic windows extend the lifespan of the X-ray tube while ensuring high transmittance; ceramic grids and collimators more precisely shape the beam, reducing scattering and improving image contrast and clarity while lowering the additional radiation dose to patients.

We are committed to becoming a key partner for medical imaging equipment manufacturers, providing the underlying material guarantee for more accurate, safer, and more reliable imaging through the extreme physicochemical stability of ceramic materials.

Laser therapy device

In the field of laser therapy devices, we provide core ceramic component solutions, from thermal management to optical stabilization, to ensure the accuracy, reliability and safety of laser output in all aspects.

1. Laser Thermal Management and Power Stabilization

Scenarios and Pain Points: Laser diodes and core optical components generate significant heat during operation. Uneven heat dissipation can lead to wavelength drift, power fluctuations, and even component failure, directly impacting treatment effectiveness and equipment lifespan.

What We Can Do: We provide high thermal conductivity ceramic components such as Ceramic Heat Sinks and thermally conductive substrates for heat dissipation of core heat-generating components.

What We Achieve for You: The high thermal conductivity of ceramic components allows for rapid and uniform heat dissipation, stabilizing the operating temperature of core components within ±0.5℃. This ensures long-term stability of laser output power and wavelength, improving treatment consistency and equipment reliability.

2. Precision Positioning and Stabilization of the Optical System

Pain Point: Even slight displacement or angular deviation of optical components such as mirrors and lenses within the laser resonant cavity can lead to optical path misalignment and energy attenuation, affecting treatment outcomes.

What We Can Do: We provide alumina and microcrystalline ceramic optical component supports, mirror bases, and adjustment rings. These components possess extremely low coefficients of thermal expansion and ultra-high dimensional stability.

What We Achieve for You: Our Ceramic Structural Components exhibit virtually no deformation during equipment operation or changes in ambient temperature, providing a "zero-drift" physical reference for the optical components. This ensures long-term precise alignment of the laser optical path, maintaining optimal output energy and beam quality.

3.Treatment Head Durability and Biosafety Protection

Scenarios and Pain Points: Treatment heads come into direct contact with patients or the environment, requiring tolerance to prolonged disinfection and high-temperature, high-pressure sterilization, while also possessing excellent biocompatibility to avoid the risk of cross-infection.

What We Can Do: We provide zirconia or alumina ceramic treatment head shells, light emission windows, and internal insulating sleeves.

What We Achieve for You: The ceramic shell possesses extremely high hardness and chemical inertness, withstanding repeated high-temperature disinfection and chemical corrosion; its excellent biocompatibility ensures safe clinical applications, providing a reliable, durable, and safe final barrier for laser treatment.

We are committed to becoming a key partner for laser medical device manufacturers, providing a solid physical foundation for the safe, precise, and long-term operation of every laser therapy device through the superior thermal, mechanical, and chemical properties of ceramic materials.

Ventilator

Ceramic components are a key guarantee for ventilators to achieve "precision life support". With "silent absolute reliability", ceramics have built a solid foundation of safety, precision and durability in the life channel of ventilators, directly ensuring the effectiveness and continuity of life support treatment for critically ill patients.

1.Precise Gas Mixing and Flow Control

Scenarios and Pain Points: The oxygen-to-air mixing ratio in a ventilator is a core parameter supporting treatment. Traditional metal or plastic components, over long-term use, can experience wear, corrosion, or moisture absorption, causing the accuracy of gas flow sensors and proportional valves to drift, directly impacting treatment effectiveness.

What We Can Do: We provide ceramic gas flow sensor cores, proportional valve cores and seats, and precision flow channels made entirely of ceramic or with Ceramic Liners.

What We Achieve for You: Ceramic components experience near-zero wear, do not absorb gas, and can withstand high-pressure oxygen environments for extended periods. This helps your device maintain stable tidal volume and oxygen concentration control within clinically required ranges throughout its years of use, eliminating treatment risks caused by measurement deviations.

2.Long-lasting Equipment Disinfection and Corrosion Resistance

Scenarios and Pain Points: Breathing circuits require frequent high-temperature, high-pressure, or chemical disinfection, and may come into contact with corrosive media such as anesthetic gases and nebulized drugs. Traditional materials are prone to aging, cracking, or releasing harmful substances, leading to cross-infection risks and performance degradation.

What We Can Do: We provide ceramic humidification tank components and breathing tubing connectors that can withstand repeated high-temperature, high-pressure sterilization at 134℃, as well as ceramic nebulizer components resistant to drug corrosion.

What We Achieve for You: Our ceramic components possess perfect chemical inertness and thermal stability, maintaining performance even under long-term, harsh disinfection and corrosive environments. This effectively extends the lifespan of core consumables, helping you reduce equipment operation and consumable replacement costs, while providing patients with a reliable biosafety barrier.

We focus on leveraging the extreme stability of ceramic materials to provide solutions for critical flow paths and functional components in life support equipment, helping you achieve long-term reliable equipment performance and safeguarding the safety and precision of every breath.

Leave A Message

Scan to Wechat :

Scan to WhatsApp :