Ceramic components enhance equipment precision, reliability, and lifespan, reducing maintenance costs while directly enabling high-speed, high-precision, and high-durability advanced manufacturing processes. They are a key supporting material for the transformation and upgrading of the manufacturing industry. Their superior hardness, wear resistance, corrosion resistance, and stability solve the extreme operating conditions challenges faced by metals and plastics in critical equipment.

Metal cutting machine tools

In the field of modern metal cutting, we provide high-performance Ceramic Tool solutions to help customers efficiently address the challenges of machining difficult materials and improve production accuracy and efficiency.

1.High-Efficiency Machining of High-Strength, High-Hardness Materials

Industry Scenarios: When machining materials such as hardened steel and high-temperature alloys, traditional cutting tools suffer from rapid wear and low efficiency, hindering production cycle time and costs.

Ceramic Solutions: Providing silicon nitride-based and alumina-based composite ceramic turning and milling inserts and specialized boring tools, with optimized groove shapes and microstructures tailored to material properties.

Core Value: Significantly improves machining efficiency and tool life. Ceramic tools can operate stably at cutting speeds several times higher than cemented carbide tools, greatly increasing metal removal rates and extending tool change cycles several times over, enabling efficient continuous machining of difficult-to-machine materials and reducing unit costs.

2.High-Precision, High-Surface-Quality Finishing and "Turning Instead of Grinding"

Industry Scenario: When performing high-precision, high-surface-finish finishing on hardened workpieces (HRC>50), grinding processes are inefficient and lack flexibility, making carbide tools unsuitable.

Ceramic Solution: Providing sharp-edged silicon nitride ceramic and cubic boron nitride composite finishing inserts suitable for high-precision turning and milling.

Core Value: Providing an efficient and flexible alternative to precision machining. Ceramic inserts can complete finish turning or finish milling in a single setup, achieving a surface finish of Ra<0.2μm and strict tolerances, significantly shortening the process flow, reducing reliance on dedicated grinding machines, and improving manufacturing flexibility.

3. Dry Cutting and Green Manufacturing

Industry Scenarios: To reduce costs and environmental burden, dry or micro-lubricated cutting is becoming increasingly popular, placing stringent demands on the high-temperature performance of cutting tools.

Ceramic Solutions: We offer a series of ceramic cutting tools specifically designed for dry, high-speed cutting, enhanced with materials and coatings to ensure high-temperature stability.

Core Value: Facilitating green and efficient dry machining. Ceramic tools maintain high hardness above 800°C, making them suitable for coolant-free cutting. This significantly reduces or eliminates the use of cutting fluid, saving costs and creating a more environmentally friendly production environment while maintaining high machining efficiency.

We are not only a supplier of Ceramic Cutting Tools, but also your process partner for enhancing metal processing capabilities. Through in-depth collaboration with our clients, we analyze specific workpiece materials, process requirements, and processing pain points, providing comprehensive support from tool selection and parameter optimization to production line upgrade suggestions, helping you transform "processing challenges" into "efficiency advantages."

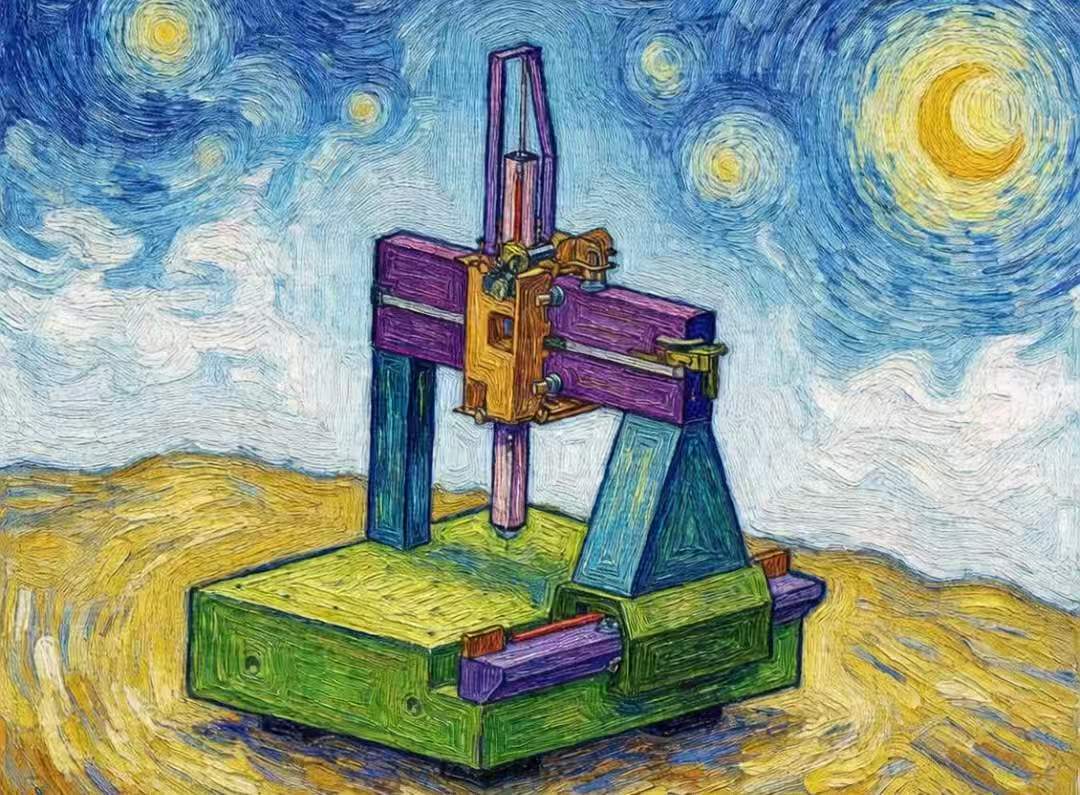

Precision measuring equipment

In the field of ultra-precision measurement and scientific instruments, we provide core ceramic structural component solutions, using the extremely low thermal expansion and ultra-high stability of ceramic materials to build a reliable foundation for measurement standards and optical systems.

1.Precision Coordinate Measurement and Benchmark Traceability

Industry Scenarios: In metrology and precision manufacturing, the metal or granite references of equipment such as coordinate measuring machines (CMMs) undergo micron-level thermal deformation due to temperature fluctuations. Long-term wear can also lead to accuracy drift, affecting measurement consistency and reliability.

Ceramic Solutions: We provide ceramic grating ruler substrates, guide rails, probe assemblies, and integral ceramic platforms made from near-zero expansion ceramic materials. Precision grinding and processing ensure excellent dimensional stability.

Core Value: Fundamentally solves the benchmark inaccuracy problem caused by temperature changes and wear. The ceramic components have an extremely low coefficient of thermal expansion (<0.5×10⁻⁶/K), high hardness, and wear resistance. They can almost completely isolate temperature effects and resist wear, ensuring that the measuring machine maintains micron/submicron-level accuracy and repeatability over the long term, guaranteeing the reliability of the quality system.

2.High-End Optical Systems and Scientific Observation Platforms

Industry Scenarios: High-end instruments such as laser interferometers and lithography machines require platform stability down to the nanometer scale. Even minute thermal expansion or vibrations can cause optical path shifts and image quality degradation, directly impacting measurement accuracy and process yield.

Ceramic Solutions: Providing ultra-high flatness (flatness up to λ/20), low thermal expansion ceramic optical platforms, frames, adjustment mounts, and customized ceramic structural components, supporting processing and modification based on thermal and mechanical requirements.

Core Value: Creating a stable substrate with near-zero dimensional drift for optical systems. The ceramic platform and support structure effectively suppress thermal disturbances and external vibrations, providing an ideal environment for nanometer-level positioning, ultra-stable interferometry, and high-resolution imaging, significantly improving data reliability and process window.

We are not just a manufacturer of ceramic components, but also your partner in pursuing ultimate precision and stability. Through in-depth collaboration with your optical and mechanical engineers, we can translate the limits of materials science into the cornerstone of your system performance, jointly defining the standards for the next generation of precision instruments.

Chemical and process industries

In the chemical and process industries, we provide customized component solutions based on high-performance ceramics to fundamentally improve the corrosion resistance and wear resistance of key equipment, ensuring continuous, safe and stable production.

1.Long-Term Sealing and Transportation of Strongly Corrosive Media

Industry Scenarios: When transporting media such as strong acids, strong alkalis, and organic solvents, traditional metal components are prone to corrosion and failure, leading to leaks, contamination, and frequent downtime.

Ceramic Solutions: We offer mechanical seal rings, integral ceramic pump housings and impellers, valve internals, and composite lined pipes made of silicon carbide and special alumina ceramics. Materials and processes are optimized for media characteristics.

Core Value: Completely solves the problem of rapid failure and contamination caused by corrosion. Ceramic components, with their inherent chemical inertness, can withstand most corrosive media for extended periods, simultaneously resisting microparticle erosion. This extends the lifespan of critical components several times over, significantly reducing unplanned downtime and ensuring production safety and fluid purity.

2.High-Abrasion Slurry and Particulate Media Conveying

Industry Scenario: When conveying slurries containing high concentrations of hard particles, the wear on flow components is severe. Traditional wear-resistant materials have short lifespans, leading to decreased efficiency, frequent leaks, and high maintenance costs.

Ceramic Solutions: We provide ceramic impellers, guards, seals, pipe linings, and valve internals made from high-purity alumina, toughened zirconia, or silicon carbide, with reliable structural design ensuring stable installation.

Core Value: We offer solutions that extend lifespan by tens of times for high-abrasion conditions. The extremely high hardness and wear resistance of ceramic components maintain stable flow channel dimensions and reliable sealing, extending replacement cycles from weeks to years, significantly reducing maintenance costs and downtime losses, and ensuring long-term efficient system operation.

We are not only a supplier, but also your engineering partner for dealing with harsh operating conditions. Through component replacement and system upgrades, we can help you comprehensively improve equipment reliability and overall economic benefits.

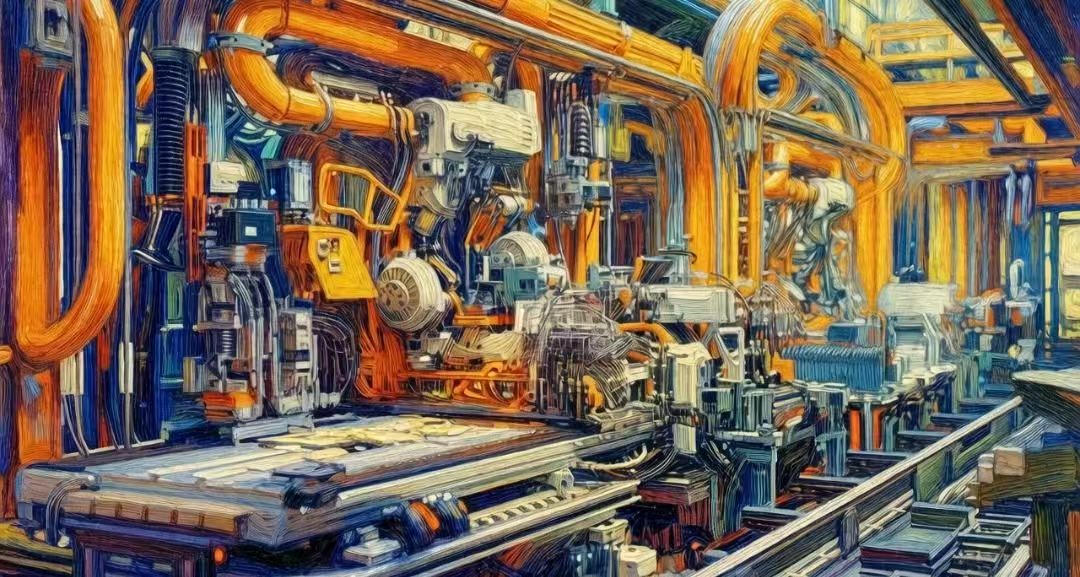

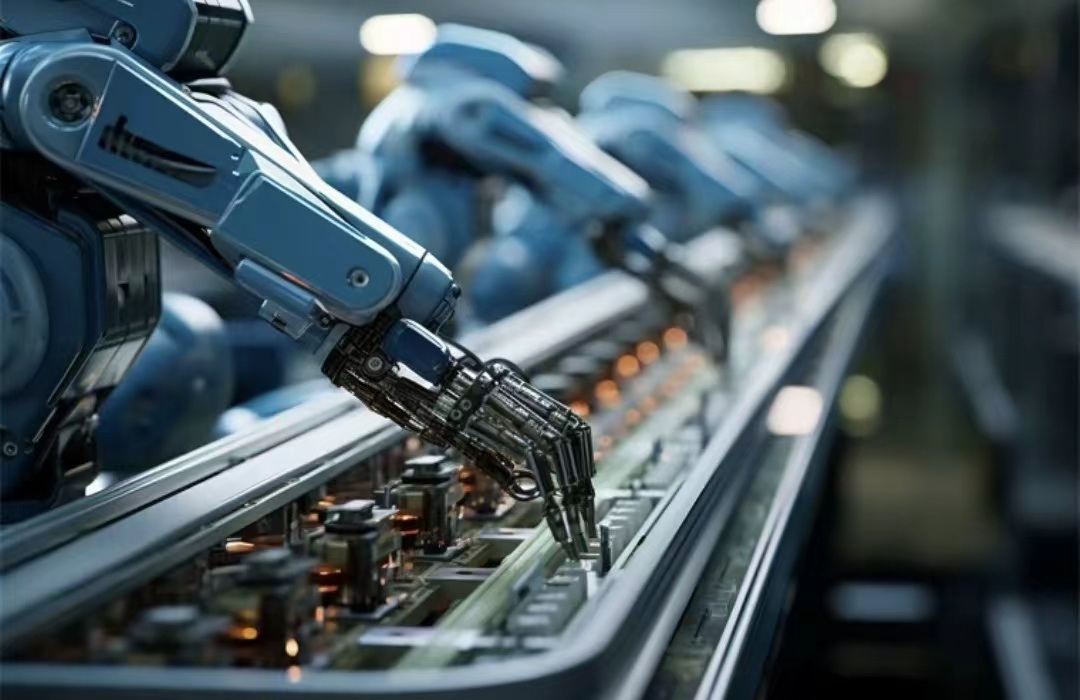

Industrial robots

In the fields of industrial automation and precision manufacturing, we provide high-performance ceramic component solutions for industrial robots, helping them break through performance limits and achieve more precise and reliable operations in high-speed, clean, and harsh environments.

1. High-Speed, High-Precision Joint Drive

Industry Scenarios: In high-paced production lines such as automotive and 3C industries, robot joints operate at high speeds and under high loads for extended periods. Traditional steel components are prone to wear and temperature rise, limiting their dynamic performance and long-term precision stability.

Ceramic Solutions: We offer Hybrid Ceramic Bearings or All Ceramic Bearings, Silicon Nitride Balls, and lightweight ceramic arm segment structures, achieving lightweight, high-rigidity, and long-lasting wear resistance for motion joints.

Core Value: Directly solves dynamic performance bottlenecks and frequent maintenance issues. Ceramic components significantly reduce wear and temperature rise, support higher acceleration and repeatability, extend maintenance cycles, and improve the robot's overall energy efficiency and stability.

2.Pollution-Free Precision Grip and Positioning

Industry Scenarios: In clean environments such as semiconductor, photovoltaic, and electronic assembly, end effectors need to achieve "mark-free" operation, free from dust, magnetism, and chemical contamination. Traditional materials are prone to particulate contamination and reduced yield.

Ceramic Solutions: We offer mirror-polished ceramic suction cups, grippers, and insulating positioning components, with customization options available based on workpiece and cleanliness level.

Core Value: Providing "zero-contamination" gripping solutions for sensitive processes. Ceramic components possess ultra-high cleanliness, non-magnetic insulation, and corrosion resistance, ensuring no physical or chemical contamination during handling, significantly improving process yield, and expanding the application of robots in harsh environments.

We are your partner in enhancing the performance of automated equipment. Based on specific working conditions and needs, we can provide customized support for ceramic components throughout the entire process, from selection to manufacturing, to jointly promote production line efficiency and quality upgrades.

Sandblasting machine

In the field of surface treatment and industrial cleaning, we provide professional ceramic component solutions to ensure the efficient and stable operation of sandblasting equipment under harsh conditions.

1.High-Efficiency Surface Treatment and Cleaning

Industry Scenarios: In industries such as shipbuilding, steel structures, and casting, sandblasting equipment is subjected to high-speed abrasive erosion for extended periods. Traditional metal nozzles wear out quickly, leading to process fluctuations, frequent replacements, and increased costs.

Ceramic Solutions: We offer high-performance Ceramic Sandblasting Nozzles and Ceramic Blasting Nozzles made of alumina and silicon carbide, along with matching ceramic venturi tubes and liners. Their inner bores are precision-machined to ensure concentrated and stable airflow.

Core Value: We solve the problems of process instability and high costs caused by wear. Ceramic Nozzles have a lifespan dozens of times longer than metal nozzles, ensuring consistent sandblasting results over the long term, significantly reducing downtime and spare parts consumption, and substantially lowering overall operating costs.

We are your reliable support for sandblasting processes, providing customized ceramic solutions based on abrasive type and operating conditions.

Leave A Message

Scan to Wechat :

Scan to WhatsApp :